Shearing Machine

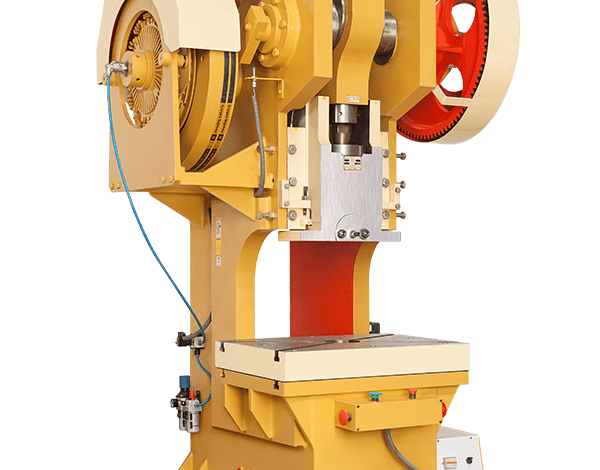

Pressure driven shearing machine is a sort of machine that utilizes the moving upper cutting edge and fixed lower. Sharp edge to apply shear power to metal plates of different thickne. In order to break and separate the plates as per the expected size. Shearing machines are a sort of manufacturing hardware. And the principle work is metal handling. The machines are generally utilized in aeronautics, light industry, metallurgy, substance industry, development, shipbuilding, car, electric power, electrical apparatuses, beautification. And different businesses to give unique apparatus and complete arrangements of hardware. C Frame Power Press

The accompanying video will show you how can it work.

What is Hydraulic Shearing Machine

The hold-down chamber of the water powered shearing machine is driven by the water driven framework to press the steel plate, and the left and right oil chamber to drive the sharp edge all over development.

The upper edge on the sharp edge transporter and the lower edge fixed on the cutting edge holders take on sensible. Edge freedom. Shear force is applied to the metal sheet of different thicknesses and isolates the

sheet as indicated by the size of the necessary crack. The water powered shearing machine is generally utilized in a wide range of metal materials, to meet the different. Interest for direct shearing. It is mostly applied in steel producing, shipbuilding, auto. Holder assembling, and switch electrical apparatuses,. Hardware fabricating, light industry, and so on.

Working Principle of Hydraulic Shearing Machine

As we put toward the start of the post, the sheet metal shearing is acknowledged by upper and lower sharp edge development driven by the water powered framework.

Various Types of Hydraulic Shearing Machine

The plate shearing machine can be partitioned into two classifications: water powered shears and mechanical

shears.

Because of the huge energy utilization and extreme clamor of mechanical shears, pressure driven shearing

machines are substantially more broadly been utilized.

As per the sharp edge transporter development, the water driven shearing machine can be partitioned into:

water powered swing pillar shears.

Pressure driven guillotine shears

Coming up next is the different kinds of the shearing machine:

guillotine shear,plate shear

One edge one the shearing machine does the responding direct movement comparative with the other sharp edge to acknowledge sheet metal cutting reason. Hand guillotine shear, hand plate shear

Hand-driven shears.

water driven guillotine shear,hydraulic plate shear

Water powered driven shears.

turn sharp edge shear,swing bar shear

The upper sharp edge transporter of the shears is swung around the turn.

pressure driven turn cutting edge shear,hydraulic swing pillar shear

A water powered driven swing pillar shears.

multi-strip slitter, coil cutting shear

Utilizing different circle scissors to cut the loop into a various strips with the expected width.

multiband slitter, sheet cutting shear

Utilizing various circle scissors to cut the metal plate into different strip with the expected width.

Snacking machine

The plate is handled into any shape by step.

Round shear,rotary shear

The shearing machine with a couple of revolving cutting edges to cut plate in the straight line or bended line.

general ironworker for punch,bar and area shear

A machine with two elements of punching and cutting.

General ironworker for plate and area shear

A machine with two elements of metal plate punching and cutting.

general ironworker for punch,plate,bar and area shear

A machine with three capacities including plate punch, plate shearing and segment shearing.

general ironworker for punch,plate,bar and area shear,notching

A machine with four capacities including plate punch, plate shearing, segment shearing and scoring.

billet shear,section steel shear

Extraordinary shearing machine for steel area.

bar shear

Exceptional shearing machine for bar material.

gator shear

The upper cutting edge of crocodile shear is in scissor movement.

supporting bar shear

Exceptional shearing machine for supporting bar.

accuracy bar shear

Exceptional shearing machine for an exact shearing bar.

2. Cutting edge holder

Fixed upper cutting edge, associate with the water powered chamber, do all over straight development, pass shear force, accomplish the cutting reason. Furthermore, the backgauge component is likewise fixed on the cutting edge holder to understand the situating of the shear plate size.

3. Shear cutting edge

The upper and lower shear cutting edges made of exclusive expectation steel can be reasonable for shearing steel from low carbon steel to hardened steel sheet, upper and lower edge has four tradable cutting blade,

further developing the help life of the sharp edge.

4. Backgauge instrument

Fixed on the cutting edge holder, including the backgauge controlling engine, miniature unique change

component, backgauge lifting system, the advanced showcase gadget, transmission screw, guide bar, and so forth The development of the shearing machine backgauge is driven by the engine, and driven the running of

backgauge plug plate to acknowledge slice to-length cutting.

5. Gas tank

The gas tank introduce on the oil tank base behind the shearing machine. The left half of the tank is

the pressure driven incorporated valve block, water powered oil siphon. and primary engine. The left half of the tank furnish with an oil check and the pressure driven oil adding to the center level of the measure is alright.

6. Leeway change gadget

The best shear power can accomplish by the hole between the upper and lower edges of the

shear material and the plate thickness. Which can safeguard the existence of the edge. And assurance the item

quality. Rule of change: for the most part change the hole of 10% of the thickness of the cut material.

7. The front ally

There additionally a side holding gadget append to the work table. Which intend to guarantee that the

shear plate is opposite to the two sides.

8. Finger security plate

The finger security plate of the shearing machine introduces on the machine cinch holder, which is

mostly used to control the protected distance of the fingers. To guarantee the protected distance of the finger,

the place of the finger assurance plate should fulfill the mechanical security guideline. While setting the plate in the fence block, the finger ought not put between the plate furthermore. The shearing machine table. In the event that the plate squeeze against the finger during the squeezing process.

9. Hold down chamber

To forestall the moving of the plate during the cutting system. The hold-down chamber take on

to press the plate immovably.

10. The electric arrangement of the shearing machine

The capacity of the electric framework principally incorporates turning over oil siphon engine drive oil siphon to give the main impetus for pressure driven shears, supply control power; The control circuit is predominantly associating the solenoid valve and oil pressure in light of activity directions to drive the blade transporter all over

development to accomplish the shearing reason. Simultaneously, the electric control the stroke of the cutting edge, the ever changing development. To ease up the arrangement line. Increment and diminish the hole. And change the shear point.

The hydraulic power of the shearing machine

- It comprises the principle oil siphon. Water driven framework. Hydraulic powered chamber, pressure chamber,

- hydraulic powered pipe, and so forth hydraulic powered oil siphon gives shearing strain to pressure driven gear.

- The hydraulic framework for the most part controls the framework pressure. And water powered oil course.

- The hydraulic powered chamber utilizes to drive edge holder development to accomplish plate shearing capacity. The hold-down chamber principally squeezes the workpiece to guarantee the accuracy of the workpiece.Read more: What’s Carton Packaging? Folding Carton Packaging explained.