Milling Machine and Bandsaw Machine

Let’s start to read, this article includes the introduction, parts, operation, and types of milling machine pros, and cons of milling machine.

Introduction of Machine :

A machine is quite possibly the most compelling and adaptable sort of machine found in the assembling business. Processing is the most broadly utilized machine utilized in machine shops and present-day producing businesses from one side of the planet to the other.

It is a kind of machining measure where a shaper having different front lines is utilized to eliminate the material from the workpiece. This machine device makes up around 86% of all material expulsion measures. Find the best bandsaw machine

Milling Machine History:

The processing machine accepts to appear in 18 the century. It utilizes by the clockmakers around then. Then, at that point in the nineteenth century in the US. A machine utilize was like the machine however in this machine.

The slicing instrument used to turn and the workpiece used to stay fixed. This was the better-created type of machine.

During that time, it utilizes for the making of the firearm parts.

Later he fostered a self-loader Milling machine which further upgraded the creation. He additionally added a shaper to the machine.

Presently, these machines can play out various activities. Continuously with time now we have the most progressive type of the Milling machine which is the CNC Milling Machine. It is exceptionally precise and has a high creation speed.

Milling machine definition

The machine is a kind of machine which eliminates the material from the workpiece by taking care of the work past a pivoting multipoint shaper. The metal evacuation rate is exceptionally high as the shaper has a high velocity and many front lines. It is the main machine in the device room as virtually every one of the tasks can perform on it with high exactness.

Material Removal Rate can additionally expand by expanding the number of teeth on the shaper.

Machine Application:

- Milling Machine utilizes for Machining level surfaces, Contoured surfaces, Slotting.

- It is likewise valuable for making Complex and sporadic regions, Revolution surface, Gear cutting, Machining outside and inside strings.

- Machining helical surfaces of different cross-segments and some more.

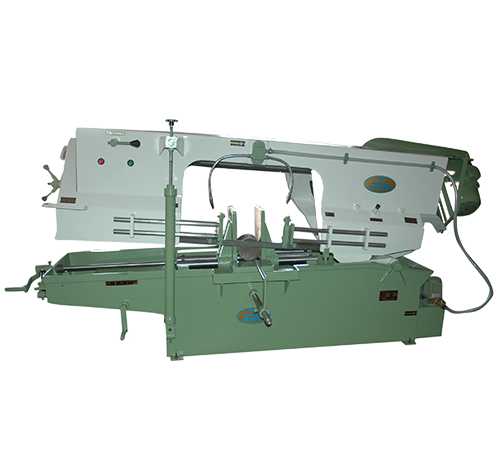

Bandsaw Machine

With all the various bandsaw types, sizes, and alternatives accessible. How would you realize which bandsaw is appropriate for you?

Various types of BandSaws

There are two principal sorts of bandsaws. Floor-standing cupboard models and units that are more limited. For mounting either on a devoted stand or on a benchtop. Cabinet models are commonly worked for proficient use, though the more modest units are more qualified for the locally established carpenter. The Cabinet models have more provisions and bigger engines, and normally highlight a more grounded outline which prompts more reliable cutting. That isn’t to say, in any case, that one can’t get proficient outcomes from a seat mounted bandsaw.

Step by step instructions to Make One Left and Right in Knitting

Fundamental Features

The two central concerns to think about while picking a bandsaw are the profundity of the slit and the jugular. The saw’s profundity of cut is the separation from the table to the upper cutting edge guides. Many bandsaws are promoted on this element alone. Which tells the planned purchaser how thick of stock can cut utilizing the bandsaw. Notwithstanding, a few saws that have just a six-inch profundity of cut can have a discretionary riser added to the unit which expands the profundity from six creeps to twelve. This permits some more affordable saws to have the option to cut thicker stock, especially while resawing.

Cutting Edge

The throat is the separation from the cutting edge to the upward edge part of the body of the saw. This distance decides the width of the cut that can finish on the bandsaw. The throat on an unsupported cabinet bandsaw normally surpasses the 12 to 14-inch throat of more modest. Seat top models. At the point when you see the expression 18-inch Bandsaw publicize. Understand that it is the throat estimation to which the producer is alluding.

Size of Motors

Another thought is the size of the bandsaw’s engine. Most home-level models join a 3/4 to 1 drive engine. Though proficient models will have bigger engines with variable velocities. For carpenters, the variable speed will not actually make any difference. As slower than max velocities ought to be fused when cutting metals. And some hard plastics.

Extra Features to Consider

Each bandsaw machine ought to have a solid metal, steel, or aluminum composite table which slants up to 45-degrees for the calculated cutting edge. The table will normally be around 16-creeps in both width and length, furnished with a miter track. Search for band wheels that have tires with cleaning brushes to keep the wheels clean. Search likewise for a unit with an inherent residue assortment port, for interfacing with your shop vacuum. Two exceptionally helpful alternatives that you should add to your band checked the weather are a tear fence and a miter measure. These two additional items will demonstrate exceptionally valuable while tearing, resawing, and cross-cutting.

Set-Up

When setting up your bandsaw. Read the guidelines that go with the unit cautiously. There are various fine changes. That is vital for the bandsaw to cut appropriately. Inability to adhere to these guidelines. Which incorporates setting the sharp edge pressure. And changing the cutting edge guides, push bearing. And side direction, will diminish the exhibition of the saw and make edges significantly more prone to break.

Not exclusively will the main person’s manual assist you with setting up your saw appropriately. Yet it will likewise assist you with turning out to substantially more acquainte. With the legitimate strategies for securely cutting with your saw. A bandsaw is among the most secure of force carpentry instruments. However, the saw should set up appropriately before use. A bandsaw is a great apparatus to work with however just whenever utilized effectively.

Cutting Wood

A machine that utilizes for cutting wood, metal, plastic, and an assortment of materials into straight. Bended or unpredictable shapes known as a level bandsaw. A wide scope of bandsaw types of gear is accessible on the lookout. They produce using cast iron, steel, or aluminum amalgam.

Sharp edge

The sharp edge comprises a constant band of metal that has teeth on one edge. These teeth utilize to cut various bits of work. The sharp edge of the machine held either by guide squares of course. The saw sharp edge is gotten between two wheels or pulleys. One of the wheels called the determined wheel fix set up and it gives the capacity to the saw. The other wheel is the idler wheel which utilizes to make the edge in the saw tight or free. A level bandsaw machine is a flexible power device and a basic device in numerous studios. The workpiece cinche set up and afterward. The sharp edge slides down through the workpiece and cuts it. A sprayer and a siphon keep the workpiece shrouded in a cutting liquid so the metal doesn’t overhead and it very well may be cut without any problem.

Specific completing cut

These are generally utilize for paring the stock down. The specific completing cut is made on more exact hardware. Amazing cuts save a ton of time and stock evacuation cutting makes it a lot quicker. The flat bandsaw gadget regularly used to cut enormous bits of work. Wood, or metal. And various edges make various cuts. They have a higher cutting pace and better exactness. These are truly reasonable for cutting long bars into various shapes.

Intended for smooth and vibration-free working. The affordable and low commotion apparatuses offer the most extreme yield and least wastage. The level bandsaw machines broadly utilized in auto, electronic, electrical, carpentry, and so forth.

Various sorts of sharp edges

Various sorts of sharp edges are utilized for various materials. A jewel sharp edge utilizes to cut glass, a portioned cold saw cutting edge utilize to cut the primary cylinder. And a manufacturing edge utilizes aluminum. metal, or copper. To cut steel tubes, holy messenger cuts and decking, grinding. And hot saw edges are utilized. Ferrous applications, cutting expulsions, flimsy divider tubing, bar stock, holy messenger iron. And level bars are cut with strong fast steel saw edges. Round blades utilize to cut elastic, fiberglass, and aluminum. Carbide tipped saw cutting edges utilize to cut aluminum, metal, copper, and bronze.

Read more: Client Testimonials – A Strategic Alliance for The Brand